Loading and unloading technology

Choose practical, safe, and reliable solutions for the correct and effective loading and unloading in your industry.

Hydraulic ramps are essential systems for the quick and safe handling of products from warehouses. They offer maximum robustness by bridging the gap between trucks and the ramp, thereby compensating for the height difference for safe and smooth transport.

Sealing bellows protect goods and personnel from weather conditions and drafts, saving energy even during loading and unloading. They are ideal for all uses and adapt to all trucks.

Loading stations combine hydraulic ramps and sealing bellows, creating an integrated unit for maximum safety. They are the easy and ideal solution, as they can be retrofitted into existing buildings, fully utilize storage space, and reduce construction costs.

Hydraulic Ramps

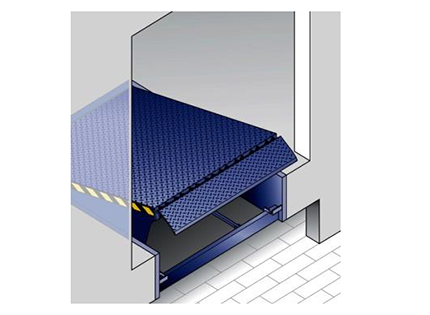

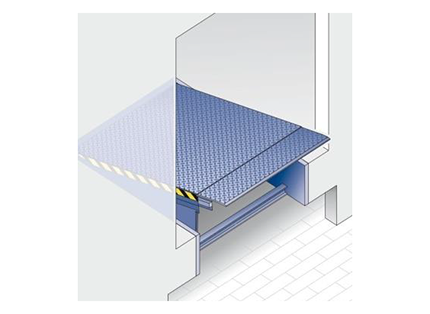

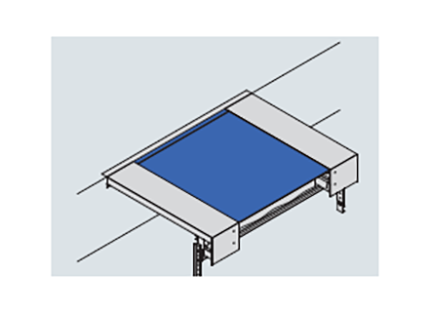

Hydraulic ramps are well-designed solutions for accurately compensating for the difference between the floor of each truck and the loading ramp for easy and safe unloading. They consist of 2 lifting cylinders and one lip cylinder, to be able to respond to all possible situations. They are also equipped with safety stop valves on the lifting cylinders, which activate instantly in case of incorrect operation or premature departure of the truck to prevent accidents. Depending on your needs, they are available in two categories:

Type HLS-2 with Hinged Lip

The HLS-2 hydraulic ramp with a 450mm hinged lip is the ideal choice for transporting particularly heavy goods. It is made of non-slip steel and can withstand up to 180kN. It is also characterized by its quick and safe start. At the beginning of operation, the electro-hydraulic system raises the platform to the highest position and automatically opens the hinged lip. Then, it lowers until the lip touches the loading surface.

Another significant advantage is the hinges, which are of open construction to prevent the accumulation of debris. Their ribbed shape, combined with the special arrangement, provides the ramp with maximum stability.

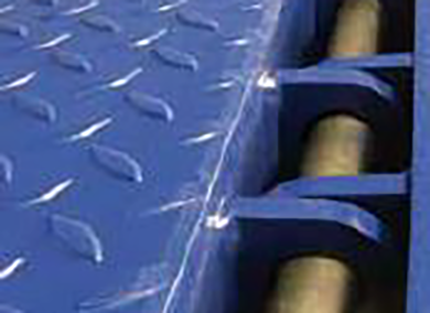

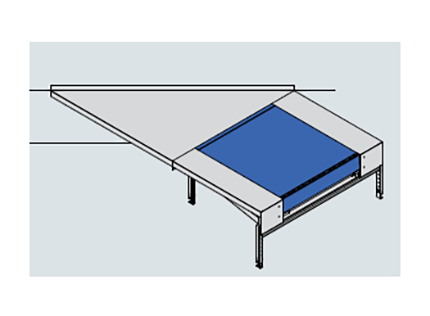

Type HTL-2 with Telescopic Lip

In the HTL-2 hydraulic ramp, the telescopic lip can extend or retract from 500mm to even 1000mm with centimeter precision, using specialized control buttons. This allows you full control of the ramp and enables you to utilize the entire loading surface.

The robust platform is made from bulb-shaped sheet metal, with an option for a sandblasted surface or polyurethane coating. It is designed to withstand a load of 60kN, and upon request, up to 180kN.

The telescopic lip is made from bulb-shaped sheet metal and features slots into which the beams are welded. This design minimizes the risk of damage from incorrect handling or improper weight support and ensures uniform and consistently reliable sliding.

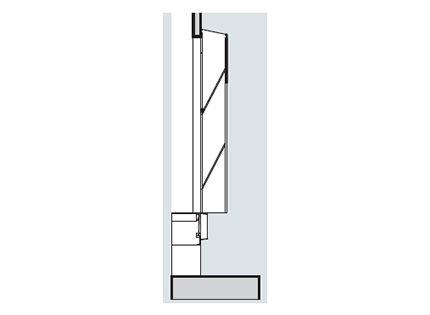

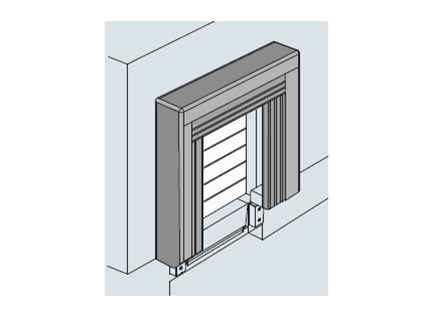

Additionally, the ramps can be installed internally within your space, behind the door, providing better thermal insulation.

Control Systems and Components

Automate your hydraulic ramp with the HÖRMANN control unit. A comprehensive solution with high resistance to external conditions and impacts, offering limitless possibilities.

Basic Control System

Multiple control systems with features such as operation and fault indicators, a service menu with maintenance cycle counters and fault analysis, and connections for external components including switches, sensors, photo cells, ramp lights, and driver registration

Protective Bellows

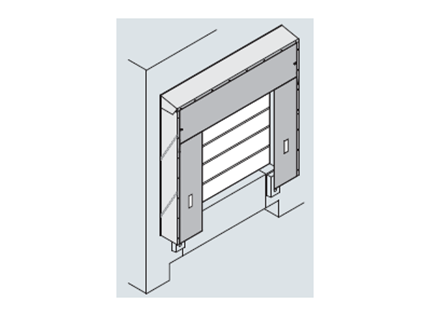

The bellows are specially designed to protect transported goods and personnel from weather conditions, prevent drafts, and save on energy costs. The central and side panels, made from double-reinforced fabric with monofilament fibers coated with PVC, combined with the galvanized, pressed frame, create a stable, flexible, and tear-resistant structure.

They fit perfectly to all truck sizes, even if the parking is not done with precision, the sealing will always function. This is due to the construction of the arms, which connect the front and rear frames. They are flexible and prevent damage from impact.

Basic version of bellows type DS

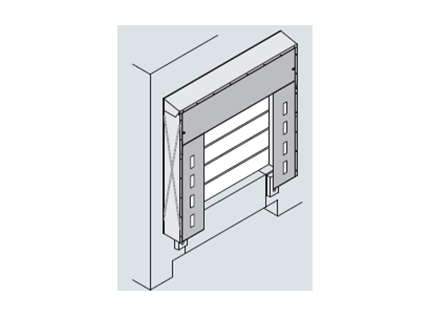

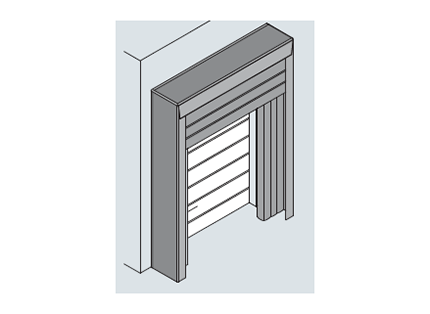

DT Type Bellows for Higher Frequency of Use

DT bellows are the ideal solution for operations requiring 24/7 loading and unloading. They are distinguished by their long lifespan and minimal maintenance costs. Optionally, for additional safety and support, corner cushions can be installed.

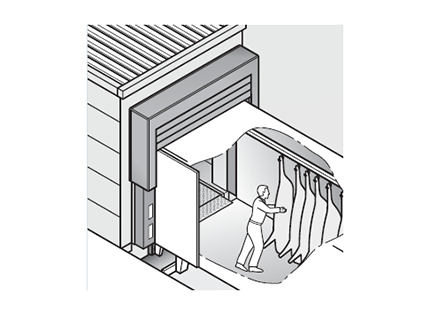

Inflatable Bellows of Type DAS - DAK

The DAS-DAK type bellows consist of inflatable cushions, specially made from durable curtain material. They provide excellent sealing and significantly prevent the infiltration of external temperatures into the building, making them the ideal solution for cold storage facilities or for extended loading and unloading times. After the truck is parked, the fan inflates the bellows around the vehicle and completely seals the loading area within seconds. When loading is complete, the fan is turned off, and the cushions deflate quickly and easily with the help of internal wires and counterweights. The DAK-3 type is particularly recommended for hanging goods such as fabrics and meat transport. The loading opening remains fully open, thanks to the inflatable top cushion, allowing goods to be transferred directly to the transport system.

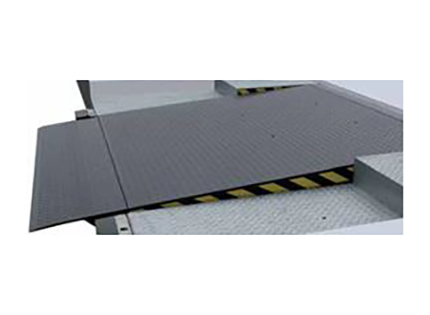

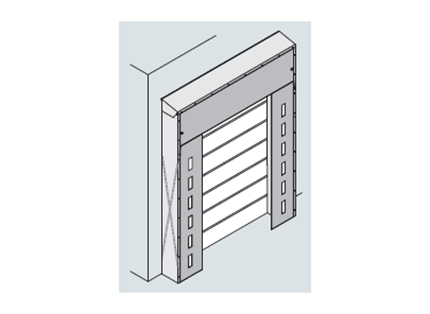

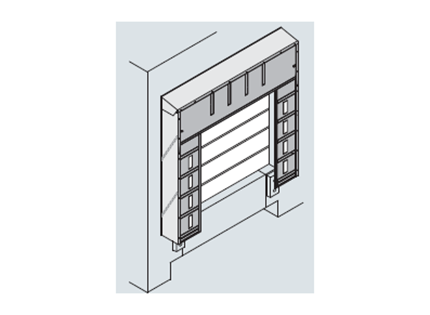

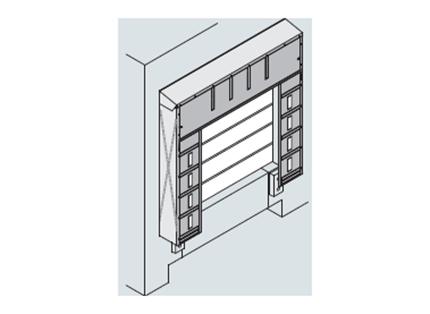

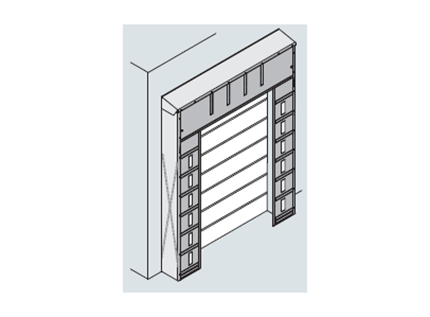

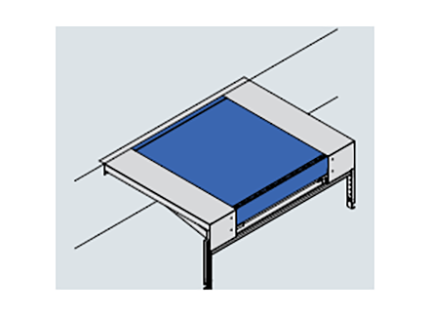

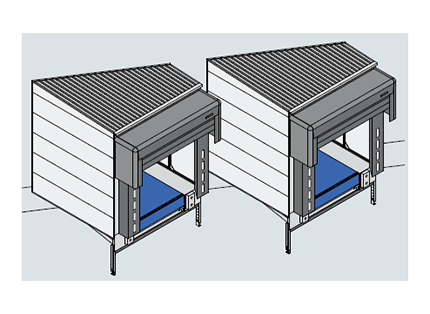

Platforms and Loading Stations

The bellows are specially designed to protect transported goods and personnel from weather conditions, prevent drafts, and save on energy costs. The central and side panels, made from double-reinforced fabric with monofilament fibers coated with PVC, combined with the galvanized, pressed frame, create a stable, flexible, and tear-resistant structure.

The cladding of the platform on the walls and ceiling is made from special “sandwich” panels with polyurethane, offering sound insulation, thermal insulation, and safe loading and unloading.

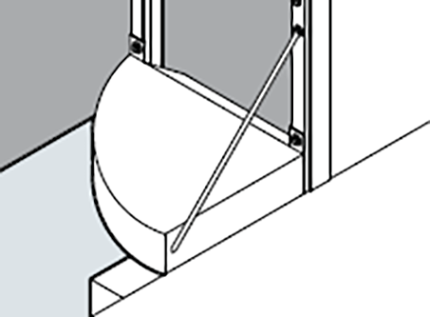

At the base of the platform, you have the option to choose between the HLS-2 or HTL-2 hydraulic ramp type, and the configuration with special corner fittings at 30°, 45°, or 60° to save space and provide a wider maneuvering margin.

Gallery

Call us immediately to do a free economic and technical study in the area you are interested in.