Industrial roller shutters

Industrial roller shutters are designed for industries where door sizes are much larger and where usage frequency demands are high. They do not have consumables resulting from usage frequency, such as springs, because in industrial settings, roller lifting is achieved through heavy-duty industrial motors, which are side-mounted. Industrial roller shutters do not have limitations on the size of the opening selection, on lifting weight, and usage frequency can be continuous.

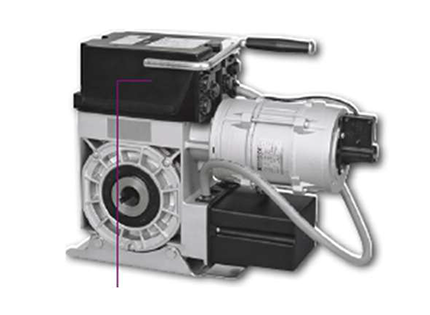

Industrial three-phase and single-phase side-mounted motors for shutters weighing from 200 to 2200 kilograms with direct drive transmission. With the option of manual operation with a crank or chain. Manual operation in industrial settings is done with a crank when the shutter is at a low height and with a chain when it is at a high height. One disadvantage of industrial shutters is that they open much slower manually compared to those with springs.

Our company works with industrial roller shutters, direct drive motors from the leading SIMU and SOMFY French manufacturers.

Click here to view the products in the catalog.

An advantage of SIMUBOX SI motors is that they do not require a separate parasolter or speed controller because it is integrated into the motor. Additionally, SI motors are manufactured by the largest and most reliable German company GFI.

Parasolters . Parasolters or speed controllers measure the speed of the roller shutter downwards and interrupt it if this speed exceeds the permissible limits. In some larger models, the parasolter is integrated into the motor. The parasolter should be connected to the motor to interrupt its operation in case of a malfunction.

Gallery

Call us immediately to do a free economic and technical study in the area you are interested in.